- in-depth waterproofing and protection slurry

- permanent active

- applied to pressure or non-pressure concrete face

- approved for drinking water structures

- grey

PRODUCT DESCRIPTION

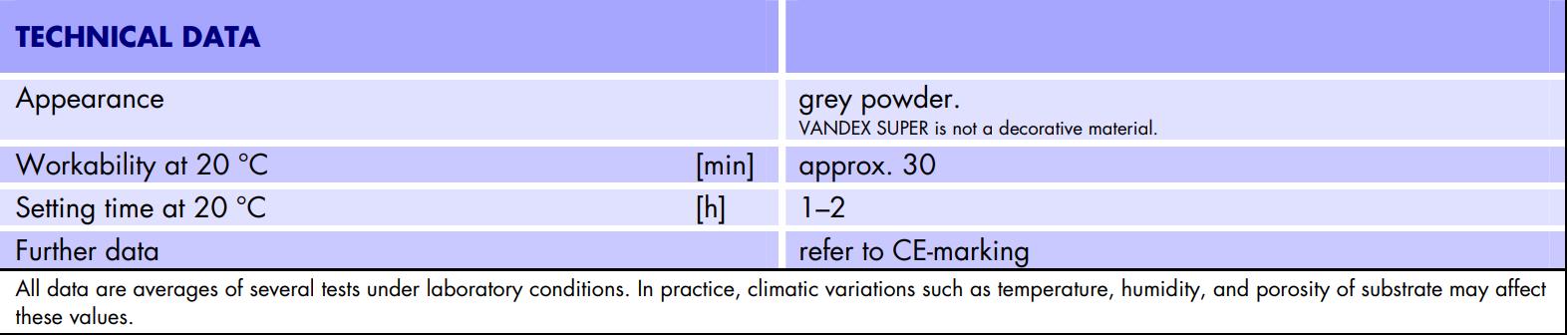

VANDEX SUPER is a cementitious, ready-mixed, in-depth waterproofer. VANDEX SUPER is based on grey Portland cement.

AREAS OF APPLICATION

- substrate: concrete

- active or passive waterproofing and protection againstwater and moisture

- foundations, slabs, retaining walls, construction joints,sewage treatment plants, swimming pools, backfilledstructural elements, etc

- drinking water structures

PROPERTIES

It consists of grey Portland cement, specially treated quartz sand and a compound of active chemicals.When VANDEX SUPER is applied to a concrete surface the active chemicals combine with the free lime and moisture present in the capillary tract, to form insoluble crystalline complexes. These crystals block the capillaries and minor shrinkage cracks in the concrete to prevent any further water ingress (even under pressure). However, the Vandex layer will still allow the passage of water vapour through the structure (i.e. the concrete will still be able to “breathe”). In addition to waterproofing the structure, VANDEX SUPER protects concrete against sea water, waste water, aggressive ground water and certain chemical solutions. VANDEX SUPER is tested for use in contact with drinking water.

SURFACE PREPARATION

The substrate to be treated must be sound and even, openpored, roughened and its surface free from voids, large cracks or ridges. Any adhesion reducing substances like bitumen, oil, grease, remains of paint or laitance have to be removed by suitable means.

Water leaks must be stopped e.g. with VANDEX PLUG. Thoroughly moisten the substrate, it must be damp but not wet at the time of application. Any surface water on horizontal surfaces must be removed.

MIXING

Mix by volume 5 parts of VANDEX SUPER with approx. 2 parts of tap water (25 kg + approx. 7–8.5 litres) in a clean container for at least 3 minutes to a lump-free, homogene

ous consistency of thick oil paint. Use a mechanical mixer.

BACKFILLING

Backfilling can be carried out 3 days after completion of the Vandex treatment

PLASTERING/COATING

Surfaces treated with Vandex products which are to be coated or painted should be left to cure for at least 28 days.

At the end of the curing period, prior to the application of coatings or paints, the surfaces should be saturated with water and neutralised with diluted hydrochloric acid (1:8 / approx. 3.5%). Observe precautionary measures! Following this, the area must be thoroughly rinsed with water.

When a plaster or render finish is required on top of a Vandex treatment it is essential to apply a rough cast of sand and cement on the final Vandex coat while it is still tacky. On hardened Vandex surfaces apply an appropriate bonding agent before rendering.

Coatings on top of a Vandex treatment have to be alkali resistant. Decorative coatings applied on the passive water pressure side are recommended to be water vapour permeable.

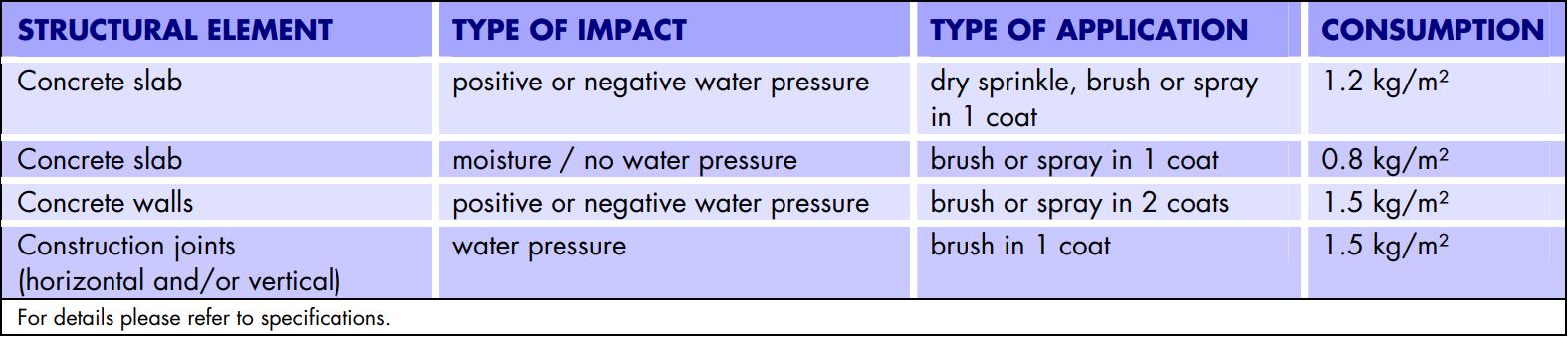

APPLICATION

VANDEX SUPER is applied with brush, suitable spray equipment or by dry sprinkling.

Brush application

Ensure that all cavities in the substrate are filled. Crosswise application: vertically bottom-up, then horizontally.

Spray application

VANDEX SUPER can be applied with a suitable fine mortar spraying device. For maximum spray pattern it should be possible to adjust volume of product as well as air pressure and volume. The nozzle diameter is approx. 4 mm. The first layer of Vandex is applied in circular motion with the spray nozzle held at a 90% angle to the substrate. The final layer can be left as a spray finish or treated to a specified finish.

Apply subsequent coat whilst previous coat is still damp at the surface. The waiting time before applying the following coat depends on local climate conditions such as humidity, temperature, etc. The previous coat must not be damaged during application of the following coat.

To maintain workability of the material do not add water, simply re-stir the mixture.

Dry sprinkle and power trowel application

The concrete is poured, vibrated and screeded as usual. When the concrete to be treated starts to reach initial set, the specified amount of VANDEX SUPER is dry-distributed by hand using a sieve (mesh size of 1 mm) or suitable spreader on to the concrete surface. The powder is then trowelled into the substrate until coverage is uniform and the specific finish is achieved.

Do not apply at temperatures below +5 °C or to a frozen substrate.

CURING

Keep damp for at least 5 days and provide suitable protection against extreme weather conditions (e.g. sun, wind, frost) while setting. The freshly treated surface should be protected from rain for a minimum period of 24 h. In closed spaces and deep pits, suitable air circulation should be provided for 24 hours following the VANDEX SUPER treatment.

FILLING OF WATER RETAINING STRUCTURES

Filling can take place when the surface treatment has hardened sufficiently, usually not less than 14 days after application. However, if earlier filling is specifically required, filling may be considered after not less than 7 days, provided the surface is thoroughly checked for hardness.

A careful cleaning and disinfection prior to the first operation is essential. Observe national laws and regulations.

PACKAGING

25 kg PE-lined paper bag

STORAGE

When stored in a dry place in unopened, undamaged original packaging, shelf life is 12 months.

HEALTH AND SAFETY

Please refer to Safety Data Sheet on www.vandex.com.

CONSUMPTION