A Green Label certified, low voc and solvent free, epoxy traffic coating system for interior car parking levels.

Cosmetically enhances multi-storey car parks,making them brighter and safer places to visit.

Environmentally Friendly:Green Label certified – 032-089 Environmentally Preferred Coating. |

|

Attractive:Brightens up dull, dark, musty car parks and suspended floors. |

|

Hard-Wearing:Hard-wearing & abrasion resistant suitable for regular vehicle traffic. |

|

Slip Resistant:Textured finish available to prevent slips and trips for car park users. |

|

UV Resistant:Provides a safe environment for car parking facilities. |

Technical Profile*

FIRE RESISTANCE |

|||

| EN 13501-1 | B fl – s1 | ||

SLIP RESISTANCE |

|||

| Method described in BS 7976-2 (typical values for 4-S rubber slider) | Dry>40, Wet depends on specification (in accordance with HSE and UKSRG guidelines) | ||

THERMAL RESISTANCE |

|||

| Tolerant of temperatures up to 60°C | |||

WATER PERMEABILITY |

|||

| Nil – Karsten test (impermeable) | |||

SURFACE HARDNESS |

|||

| Koenig Hardness Test | 180secs | ||

ABRASION RESISTANCE |

|||

| Taber Abrader (1 kg load using CS10 wheels) | 80 mg loss per 1000 cycles | ||

| BS8204-2 | Grade AR2 | ||

CHEMICAL RESISTANCE |

|||

| Contact Technical Department | |||

BOND STRENGTH |

|||

| Greater than cohesive strength of 25 N/mm2 concrete. >1.5 MPa | |||

| SPEED OF CURE | 10˚C | 20˚C | 30˚C |

| Light Traffic | 48 h | 24 h | 18 h |

| Full Traffic | 72 h | 48 h | 36 h |

| Full Chemical Cure | 12 d | 7 d | 6 d |

* These figures are typical properties achieved in laboratory tests at 20°C and at 50% Relative Humidity.

**The slipperiness of flooring materials can change significantly, due to the installation process, after short periods of use, due to inappropriate maintenance, longer-term wear and/or surface contaminants (wet or dry). Textured systems are recommended to meet slip resistance value requirements for wet conditions and/or surface contaminants (wet or dry) – please contact our Technical Advisors for

further details and specifications.

Model Specification

| System | Deckcoat EP |

| Finish | Textured |

| Thickness | Dependant on Specification |

| Manufacturer | Flowcrete Asia |

Preparatory work and application in accordance with manufacturer’s instructions.

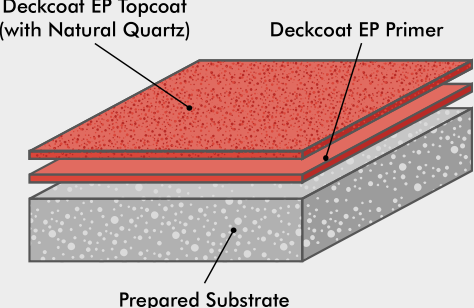

System Design (Parking Bays & Driveways)

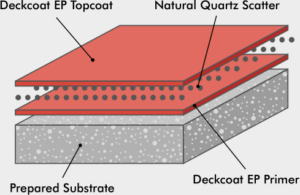

System Design (Turning Circles & Ramps)

Products Included In This System

| Primer | Deckcoat EP Primer |

| Sand Scatter | Natural Quartz |

| Finishing Coat | Deckcoat EP Topcoat |

Detailed application instructions are available upon request.

Substrate Requirements

Concrete or screed substrate should be a minimum of 25N/mm2, free from laitance, dust and other contamination. The substrate should be dry up to 75% RH as per BS8204 and free from rising damp and ground water pressure.

Installation Service

The installation should be carried out by a licensed contractor with a documented quality assurance scheme. For details of our licensed contractors, contact our customer service team or enquire via our website at www.flowcreteasia.com

Environmental Considerations

The finished system is assessed as non-hazardous to health and the environment. The long service life and seamless surface reduce the

need for repairs, maintenance and cleaning.

Environmental and health considerations are controlled during manufacture and application of the products by Flowcrete staff and fully trained and experienced contractors.

Aftercare, Cleaning & Maintenance

Clean regularly using a single or double headed rotary scrubber drier in conjunction with a mildly alkaline detergent.

Important Note

Flowcrete products are guaranteed against defective materials and manufacture and are sold subject to our standard ‘Warranty, Terms and Conditions of Sale’, copies of which can be obtained on request. Warranty does not cover suitability, fit for purpose or any consequential or related damages.

Further Information

To ensure you are specifying a fit-for-purpose floor, please consult our Technical Advisors or visit our website to register your interest in specifying one of the most durable floors on the market.